In figures

- Around 150 employees

- Schunk has one site in Ansan

- Schunk has been represented in South Korea since 1998

What do we primarily produce in South Korea?

- More than 150 million carbon brushes for automotive industry and home appliance applications in 2022

- 1.5 million silver contacts of low voltage for molded case circuit breakers in 2022

- 45.000 sintered shoes and copper blocks for railway and slip rings in 2022

What do we mainly sell in South Korea?

- Carbon brushes for Korean and overseas customers (Electrical Carbon Automotive)

- Ultra, high, low voltage circuit breakers for industry (Power Supply)

- Sintered shoes for railway and industry applications for slip rings (Rail Aftermarket)

What are the most important trends in the market?

- The market trend for secondary battery anodes and cathodes has recently increased due to the demand for batteries such as electric vehicles

- Customers are investing in new sintering furnaces to produce secondary battery anodes and cathodes, increasing the demand for graphite. The future business trend is expected to be market expansion depending on the supply and demand of graphite.

What's new in South Korea?

- To be a key supplier for shaft grounding contacts and brush holder modules for electrical vehicle traction systems of Hyundai Motor and KIA

- Development of bipolar plate for renewable energy hydrogen fuel cells

- Sales of charging systems for battery driven vehicles

...and that is only to be found at Schunk in South Korea:

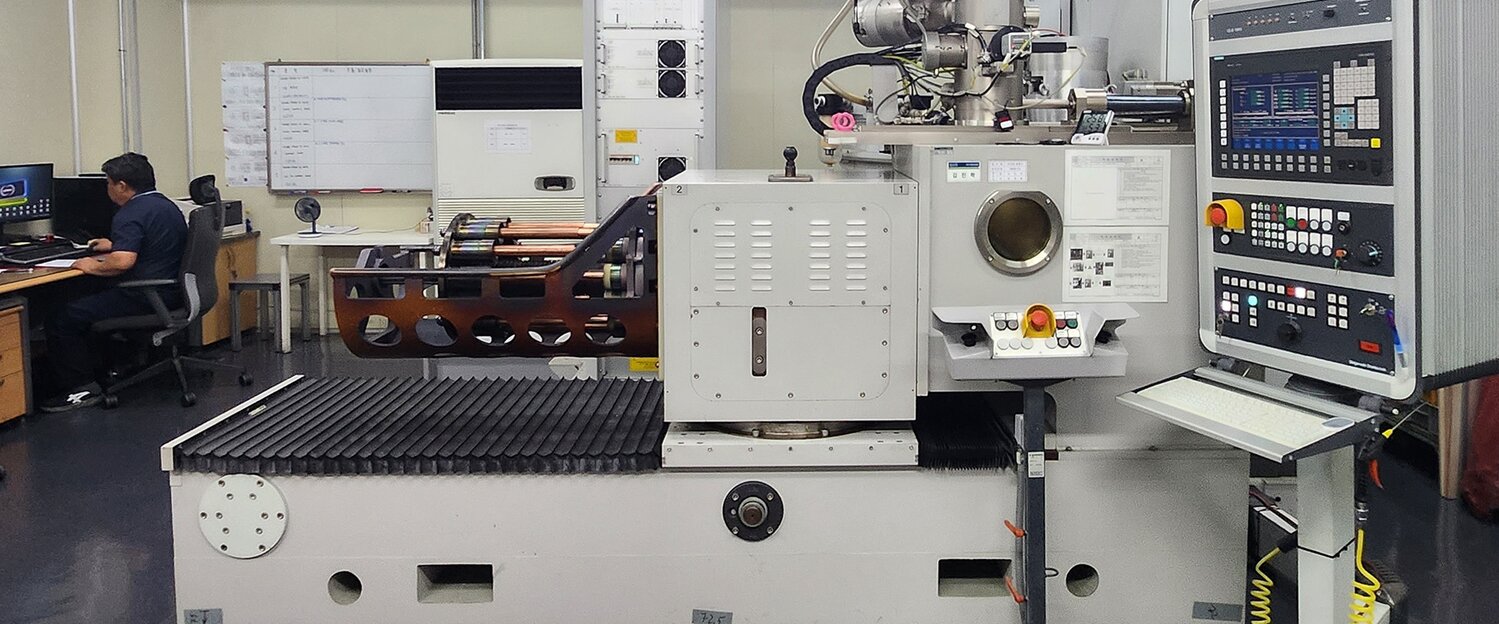

- The company operates its own research and development center and develops carbon brushes, electric contacts and metal sintered products for domestic and international markets

- Average seniority of all employees is almost 12 years (with a maximum of 35 years)

- A special event is held on the company's foundation anniversary