To conduct thermal abuse tests, or to create an environment above/below the atmospheric conditions, an external air conditioning unit is connected using a pneumatic slide valve which is capable of closing/openeing within a second.

Explosion-proof test chamber

ExtremeEvent is a device designed for conducting destructive tests on electrical components and energy storage devices. During these tests, the specimen is exposed to thermal, electrical, and mechanical conditions outside the specified range. This exposure may influence material properties and hence will allow investigation into the functional safety and nature of thermal runaway.

What makes the ExtremeEvent unique?

Coverage of international standards & norms

The ExtremeEvent can cover relevant standards / norms such as UN, SAE, IEC, UL, ISO, EUCAR, FreedomCar.

Safety with EUCAR Hazard Level 7

Specially designed for high severity hazards according to EUCAR.

Reusability of the equipment even in the event of several extreme events

The device is designed in such a way that it can continue to be used even after several thermal events such as explosions or fires without any damage to the device.

ATEX marking (gas group IIC)

For explosions with a very high rate of pressure rise (hydrogen testing).

Modular design

The modular design allows various additional options or test equipment to be selected, such as temperature control or a testing machine for mechanical tests.

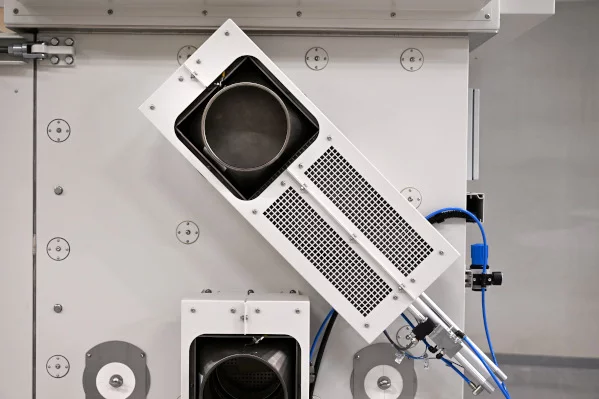

Pressure relief through patented flap mechanism

The integrated flap mechanism reduces the explosion pressure in the test chamber to a minimum and is certified in accordance with DIN EN 14797.

Explore the ExtremeEvent.

Upper Construction

The upper construction contains a patented pressure relieving flap mechanism which opens up once a threshold pressure is reached in the chamber, thus venting the gasses in a controlled manner.

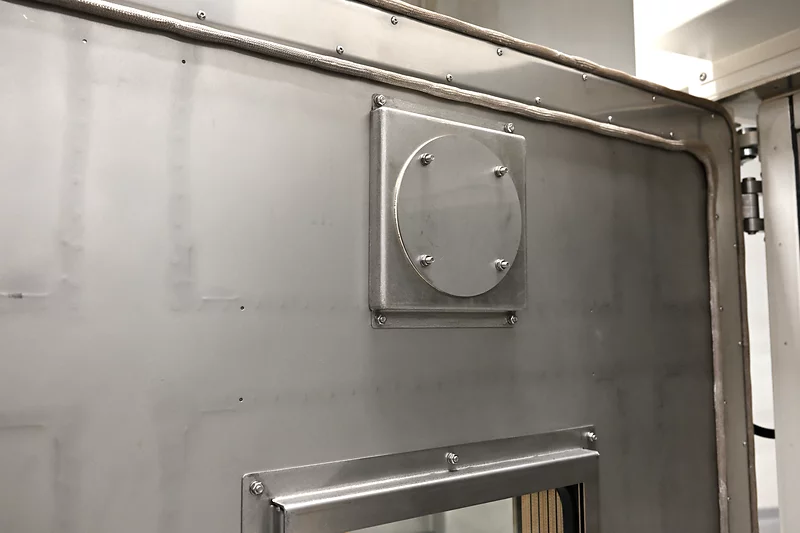

Access Ports for Sensor / Device Connection

Total 5 Access ports (two in the right, two in the left, and one in the front) made of stainless steel, providing complete flexibility in terms of external device connection. Being explosion proof and temperature resistant, they make sure there is no harm done to the externally connnected device.

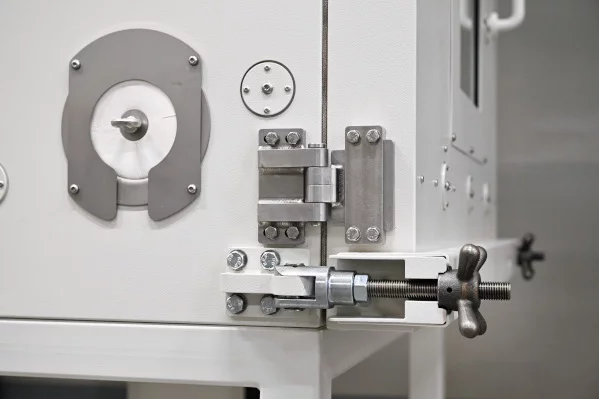

Test Space Door

The door system is attached using flexible hinges and mechanical star locks, enabling equal contact pressure and firm locking against explosion.

Innovative wall reinforcement

The test chamber is certified according to DIN EN 14460 for a pressure shock load. The innovative wall reinforcement enables a high compressive strength with a low additional weight and thus protects against possible explosions in the test chamber.

Access Ports for thermal testing

Two Access ports on the right for connecting the external conditioning unit using a pneumatic valve. The pneumatic valves are able to shut the access ports within a second to provide an isolation in case of an ExtremeEvent

Star Screws for Locking

The test space door is equipped with two extremely durable star screw locks, capable of easily handling explosion pressures, while also providing ease of handling.

Shock resistant feet

The device feet is equipped with a vibration absorbing stopper along with a metal angle for bolting(fixing) the device with the ground. This gives a stable feet against any vibrational or shock movement due to the explosion. Space above the feet enables the the installation of an N2 based inertization system, which is optional.

Video

We design the optimal solution for your application.

The ExtremeEvent was developed for the most extreme test conditions.

Abuse tests for batteries and energy storage systems: Selected safety or destruction tests from norms/standards that can cause gas generation with explosion or fire can be carried out with the ExtremeEvent. (Find out more here!)

Arc fault testing of electrical devices / components: Selected tests for electrical devices or individual components (circuit breakers, arc fault detection devices, etc.) where, for example, an arc causes high heat and pressure generation can be carried out with the ExtremeEvent.

Safety testing of pressurized hydrogen-based products: Selected tests in hydrogen-based systems (fuel cells/fuel tanks/valves) where explosions, leaks or hazardous environments may occur can be performed with the ExtremeEvent.

For specific tests and product applicability, please contact us.

Mechanical, thermal and electrical tests with one test chamber

Our ExtremeEvent enables you to carry out battery abuse tests under the most extreme conditions.

Mechanical tests: During the mechanical tests, an object penetrates or impacts the battery (mechanical integrity). For example, the extent to which nail penetration (internal short circuit) or crushing (crash) affects the functionality and safety-related behavior of the battery is examined.

Thermal tests: During the thermal tests, the batteries are exposed to ambient low to excess temperatures, with the excess temperature tests in particular leading to thermal runaway in most cases. The surrounding air is heated up to 200°C or even higher, which raises the battery to a critical temperature level after a certain time due to heat transfer processes.

Electrical tests: During the electrical tests, various critical scenarios are tested that may be present in connection with the surrounding electrical periphery. For example, a short circuit is generated (external short circuit) or the battery is deliberately overcharged to a higher voltage level. As a result, the battery heats up and also quickly enters a critical state.

Video

Reproducible battery abuse tests due to mechanical load

With previous methods for battery abuse tests, it is difficult to determine the exact and precise mechanical load that triggers the damage. The Allroundline Z100 universal testing machine from ZwickRoell is the ideal addition to the weisstechnik ExtremeEvent. Abuse tests with a maximum force of 100 kN can be carried out with the universal testing machine. Thanks to the mechanical modularity, testing tools can be changed easily and safely. The test results are analysed using the testXpert testing software.

Alternatively, a testing machine with a higher force can be provided. It is also possible to use a high-speed testing machine with impact speeds of 12 m/s or more. In principle, all types of mechanical tests can be carried out in this way.

| Testspace volume (l) | 1000 |

| Test Space Dimensions (H x W x D) (mm) | 1000 x 1000 x 1066 |

| External Dimensions (HxWxD) (mm) | 2677 x 1765 x 1664 |

| Maximum permissible rate of pressure rise (stoichiometric hydrogen-air mixture) (bar*m/s) | 500 |

| Maximum pressure surge load of the test space (bar) | 1 |

| Download spec sheet |