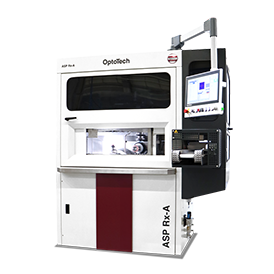

SWARFMASTER

The Rx-lens production of the future will significantly change all operations and processes. As an entry-level concept for automatic Rx production 2.0, OptoTech developed the new SWARFMASTER for high-performance pre-grinding of mineral and organic lenses (toric and freeform). By separating the pre- and fine grinding processes, you optimize your production and ultimately increase the performance and quality of your surfacing machines for mineral lenses and glass molds as well as organic lenses.

Spectacle optics

Generating

Automation

Mineral Glass

Plastic

Close

Video

Contact request

Highlights

- The SWARFMASTER is the ideal pre-cutter for all grinding and turning machines (mineral and organic lenses)

- Significant increase in grinding, turning and polishing capacity by adding the SWARFMASTER

- Can be used to replace old existing traditional mineral pre-grinding machines

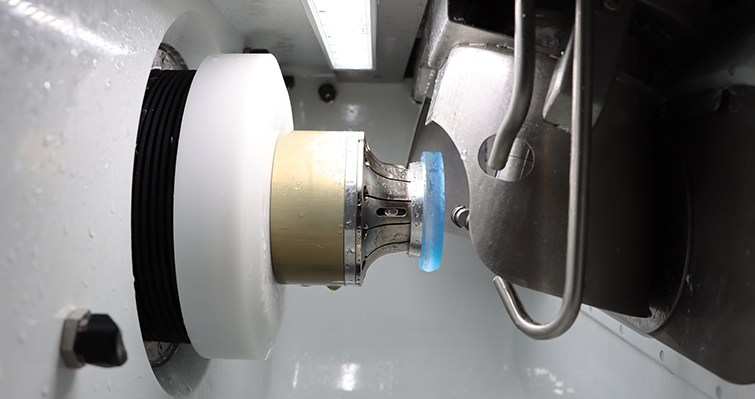

- Usage of high-performance tools (diamond grinding wheel Ø66 R4 for mineral lenses and PCD Tool ø66mm R6 HSK with 15 cutters for organic lenses)

- Adaptive toolwear: Implementation of wear improvement. Machine calibrates itself from glass to glass

- Automatic tool clamping system for quick tool change. Fastest workpiece change system due to optimized automatic handling module.

- Modular setup of the most important service parts for fastest maintenance

System advantage

- Overall optimization of production output

- Increased processing capacity

- Improving performance & quality of surfacing machines

- Improved chip management

Process characteristics

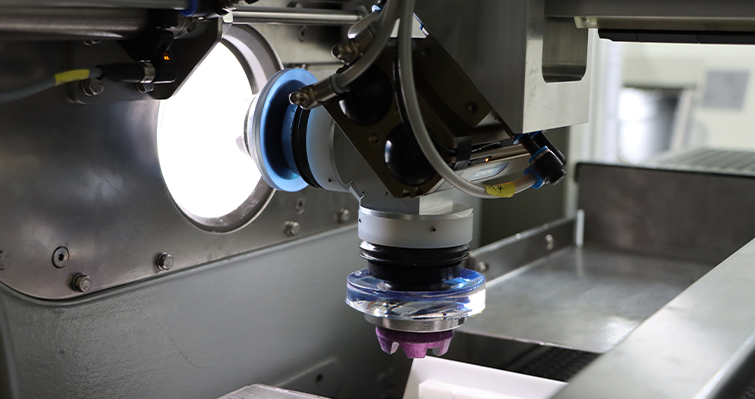

Application area: mineral lenses, glass molds and organic lenses. Backside progressives; Atorical; Individual; Front progressive; Standard toric; Blended lenses

- Mineral freeform milling of up to 60 lenses/h (depending on production mix)

- Organic freeform milling of up to 200 lenses/h (depending on production mix)

Options

- Automatic and manual version with smallest footprint available

- Barcode hand scanner

- Remote diagnostic

- LAN connection