The new CO₂ cooling technology in environmental simulation not only meets the requirements of the EU F-Gas Regulation for single-stage refrigeration systems but also accelerates processes in test laboratories. With the extended temperature range of the new test chambers reaching −50°C, changes to previous test programs are possible. In some cases, this leads to considerable time savings.

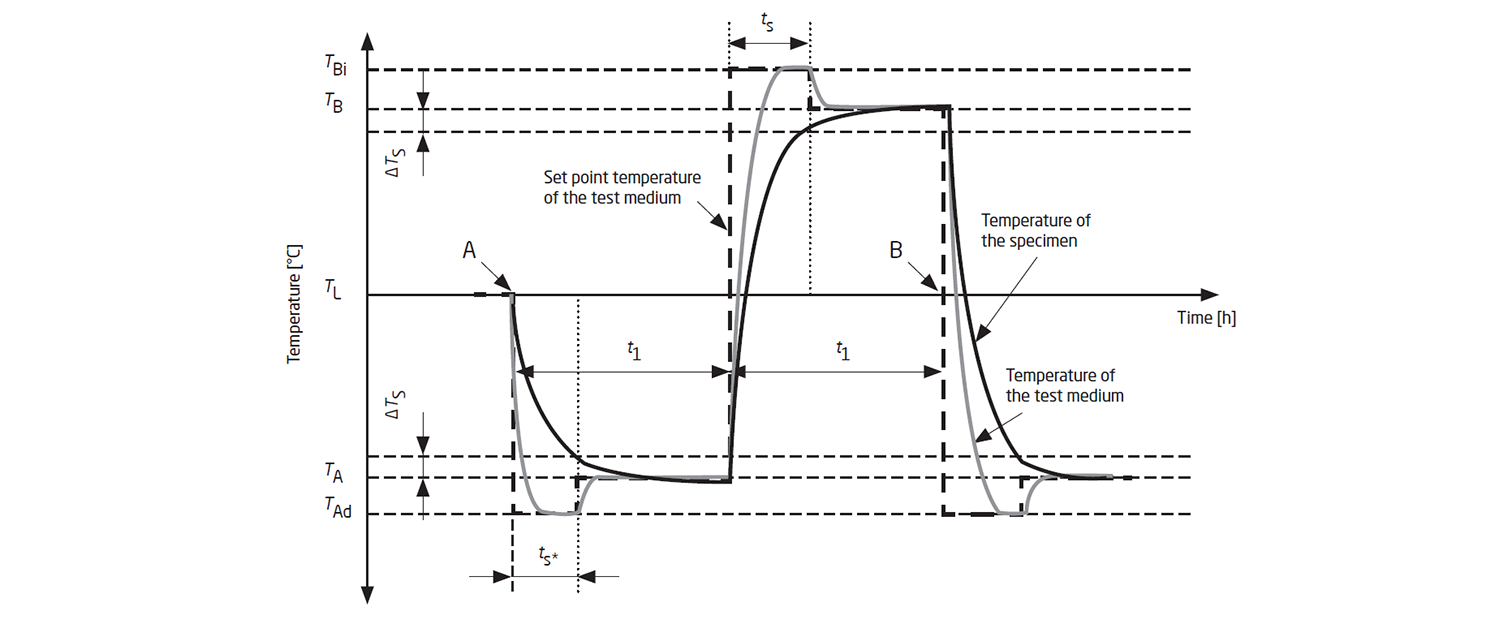

For example, according to IEC 60068-2-14 (Ed. 7) shows that test runs can be carried out in less than half the time previously required, depending on the parameters selected. A typical test situation is the testing of electronic components with the preferred temperatures TA −40°C and TB +85°C in accordance with test case Na. The “Increased Severity” described in the standard allows the temperature stress acting on the test specimen to be adjusted . The temperature set-points of the test are set below or above the target temperatures (e.g., −40°C and +85°C) for a certain period of time. Care must be taken to select the target temperatures from IEC 60068-2-1 unless otherwise specified in the relevant test specification. Based on this information, the next preferred temperature would be −50°C. It often makes sense to apply the same temperature difference of 10 K for the upper value TBi. If the set temperature of the test chamber is temporarily set to −50°C and +95°C for the “ts*” periods of the test standard, the temperature change of the test specimen can be greatly accelerated.

The real comparison of the test described, which was conducted in otherwise identical 600 l test chambers with −40°C R-449A refrigeration technology and −50°C CO₂ refrigeration technology using a 10 cm aluminum cube as the test specimen and a holding time of t1 = 10 h , produced these values:

| R449A-System | R744A-CO2-System | |

|---|---|---|

| Setpoint adjustment +85°C to -40°C | 0.3K/min | 0.5K/min |

| Setpoint adjustment +95°C to -50°C | not possible | 0.9K/min |

| R449A-System | R744A-CO2-System | |

|---|---|---|

| Setpoint adjustment +85°C to -40°C | 7:03 h | 04:01 h |

| Setpoint adjustment +95°C to -50°C | not possible | 02:14 h |

Even without “Increased Severity”, the temperature change of the test specimen is around three hours faster with CO₂ refrigeration technology. This is due mainly to the sharp drop in cooling capacity of the R-449A system with a possible final temperature of −40°C. It takes a long time to temper the test specimen from −30°C to −40°C.

The further reduction of the test time in the example is possible with the temporary temperature hold of −50°C. The incoming air quickly reaches −50°C and is regulated to −40°C only when the core temperature of the test specimen approaches the target temperature of −40°C (∆Ts). For those who want to make programming more efficient, an accessory package is available for the test chambers from Weiss Technik. This includes a temperature sensor and suitable test programs.

Time savings can also be achieved with -70°C devices. However, the energy consumption is higher. Further reductions through even greater deviations in holding temperatures are difficult because this can quickly lead to an unwanted intensification of the test (especially at high temperatures). If time saving is not the leading parameter, greater efficiency can also be achieved by increasing the number of test specimens in the test chamber that are simultaneously re-tempered. The higher performance of CO2 devices, in conjunction with the modified standard specifications, creates greater testing capacity. This also applies to tests according to IEC 60068-2-2, test cases Bd and Be.

If test chambers are to be replaced, a replacement with CO₂ refrigeration technology capable of reaching −50°C is always sufficient in the case of an old appliance with a low temperature of −40°C. In many cases, it is also possible to replace an appliance with a low temperature of −70°C at considerably lower investment costs. The cooling capacity of a -50°C test chamber with CO2 technology is about half as high at -40°C as that of a -70°C cascade. This is sufficient for the requirements of IEC 60068-2-1, test cases Ab, Ad, and Ae.

Reprint free of charge. Please cite Weiss Technik GmbH as the source.