The new CO₂ cooling technology in environmental simulation not only meets the requirements of the EU F-Gas Regulation for single-stage refrigeration systems but also accelerates processes in test laboratories. With the extended temperature range of the new test chambers reaching −50°C, changes to previous test programs are possible. In some cases, this leads to considerable time savings.

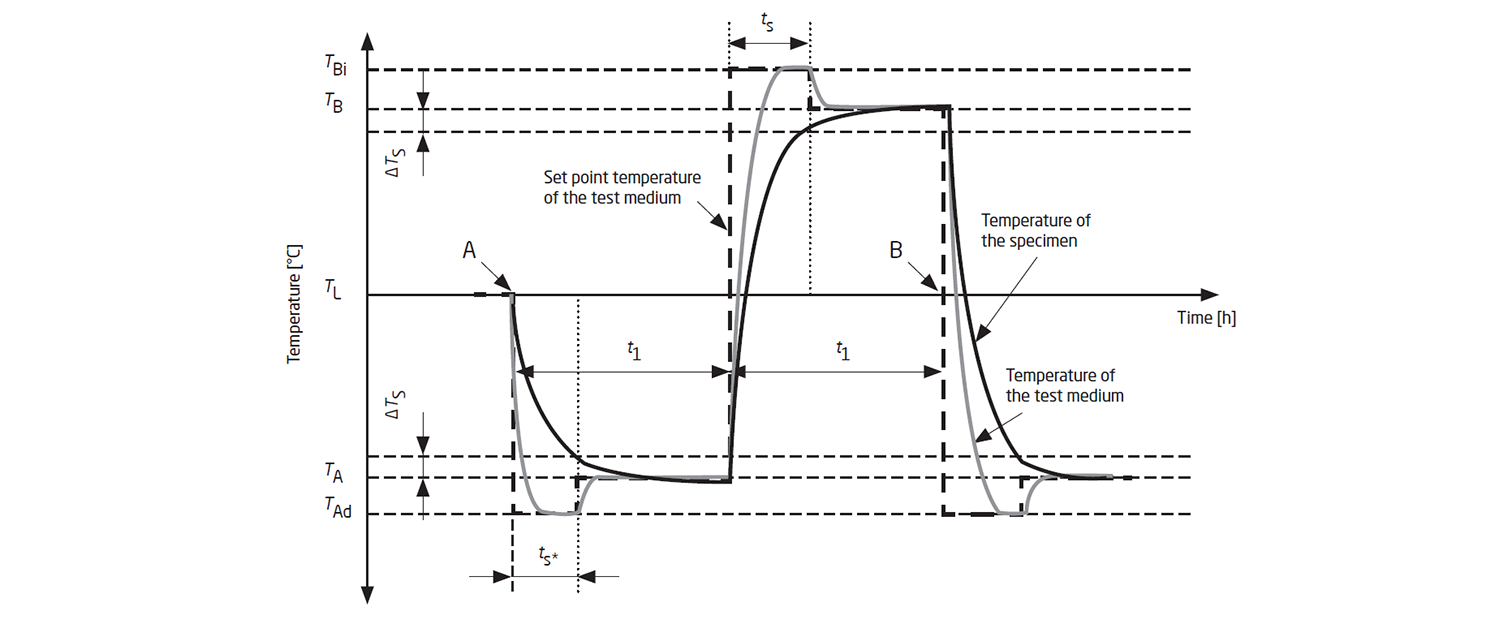

For example, according to IEC 60068-2-14 (Ed. 7) shows that test runs can be carried out in less than half the time previously required, depending on the parameters selected. A typical test situation is the testing of electronic components with the preferred temperatures TA −40°C and TB +85°C in accordance with test case Na. The “Increased Severity” described in the standard allows the temperature stress acting on the test specimen to be adjusted . The temperature set-points of the test are set below or above the target temperatures (e.g., −40°C and +85°C) for a certain period of time. Care must be taken to select the target temperatures from IEC 60068-2-1 unless otherwise specified in the relevant test specification. Based on this information, the next preferred temperature would be −50°C. It often makes sense to apply the same temperature difference of 10 K for the upper value TBi. If the set temperature of the test chamber is temporarily set to −50°C and +95°C for the “ts*” periods of the test standard, the temperature change of the test specimen can be greatly accelerated.