Refrigerants I F-gas Regulation Overview

FAQ

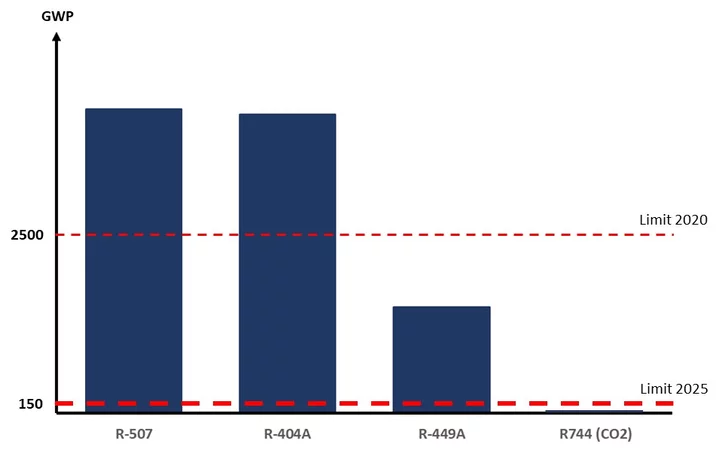

Many refrigerants used in environmental simulation systems (so-called F-gases, e.g. R404A or R23) have a high global warming potential. Since 2015, they have been replaced by more environmentally friendly variants in the EU. At WeissTechnik, we aim to build high-performance yet environmentally friendly climate chambers.

We were therefore the first supplier to deliver our appliances with R-449A from January 2018. R-469A is used for ultra-low-temperatures since 2020. Alternative refrigerants are also available. From 2025, many devices will be available with pure CO₂ refrigeration technology.

The EU Parliament has adopted the revision of the F-Gas Regulation by a large majority. The new EU Regulation 2024/573 is in force and contains the new equipment category of "self-contained refrigeration systems", for which a GWP limit of 150 for the refrigerant will apply from 2025. Chillers and devices for which no safe substitute-refrigerant is available are excluded ("compliance with safety requirements").

>> EU implementing regulation 2024/2729

Synthetic refrigerants with a GWP below 150 are not available for environmental simulation systems. Only natural refrigerants can be considered now. For safety reasons, they must not be flammable.

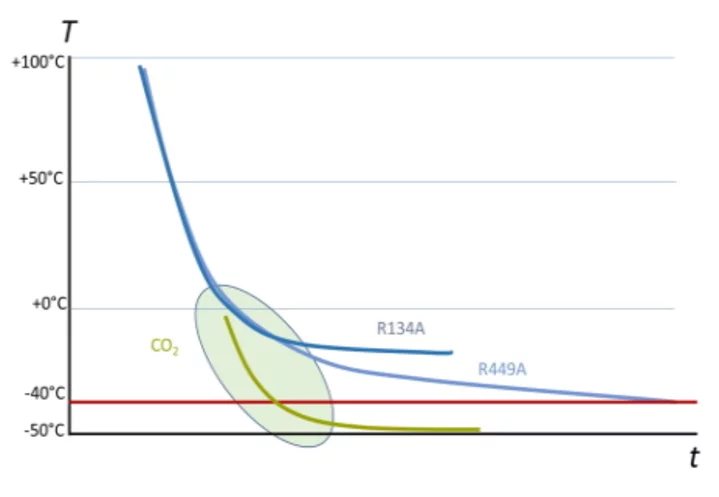

Devices and systems for environmental simulation tests typically cool and heat in temperature ranges from -40°C or -70°C to over 100°C.

Only safe refrigerants and reliable components enable the precise control and conduct of various test specifications and standards. CO₂ can now be used as a refrigerant down to -50°C thanks to the increasing availability of pressure-resistant components.

Lower temperatures can only be safely achieved with cascade systems using R-449A/R-469A/R23.

Single-stage refrigeration systems with R449A reach a minimum temperature of -40°C, but cooling slows down from approx. -25°C. Our CO₂-(R744)-systems can cool down to -50°C powerfully with the same or higher heat compensation.

This has many advantages:

The new refrigeration technology is installed in our devices without the need for design changes.

The EU F-Gas Regulation already contained regulations on refrigerant use, documentation, quotas and recycling. The operation, maintenance and repair of all Weiss Technik devices remains permitted for an unlimited period of time.

New: After repairs of the refrigeration system, there must be a minimum of 24 hours and a maximum of 30 days between completion of the repair and a leak test. This applies to all devices that were previously subject to mandatory leak testing.

The existing ban on the use of new refrigerants with GWP >750 from January 2032 only applies to devices in the -40°C class. Here, reclaimed or recycled refrigerants must be used. All refrigerants remain legal for systems that can cool below -50°C.

The new quotas for the import of refrigerants into the EU set out in Regulation 2024/573 are lower than in the previous regulation. Weiss Technik already procured and stored refrigerants with its own quota in 2019. The annual quota is sufficient to continue filling all our systems with refrigerant.

The reductions in the refrigerant quota in 2027 and 2030 are likely to make high-GWP refrigerants such as R23 more expensive. Weiss Technik can convert refrigeration circuits with the drop-in refrigerant WT77. The performance of the devices and systems remains the same.

For more information and answers to the most frequently asked questions, please click HERE

FAQ

FAQ