Electromobility is booming. That's why the BMW Group is building a new pilot plant for the production of lithium-ion battery cells in Parsdorf near Munich. Following the already successful collaboration regarding the supply of a drying room for a research facility in 2019, weisstechnik has now also been awarded the contract for this important pilot project. The focus is on safe and at the same time particularly efficient air dehumidification of the production rooms. This is because the production of the extremely dry process atmosphere needed can require up to 40 % of the energy required for battery production.

- Pilot plant for battery production

- Several room-in-room systems

- Chamber construction, air-conditioning technology, air dehumidification

- Highly efficient customised solution for low energy requirements

Extreme air dehumidification in battery production

As an established partner, weisstechnik is planning and implementing the necessary dry room and air conditioning technology for the new pilot plant. The production of highly efficient, safe and stable lithium-ion batteries for electric vehicles is a complex and extremely sensitive process. In order to be able to produce high-performance batteries in the long-term, it is important to precisely maintain the required climatic conditions in the various production steps. Deviations can negatively affect the performance and durability of the batteries, and so to prevent this, reliable and efficient ventilation technology is required that works safely, especially in the area of air dehumidification.

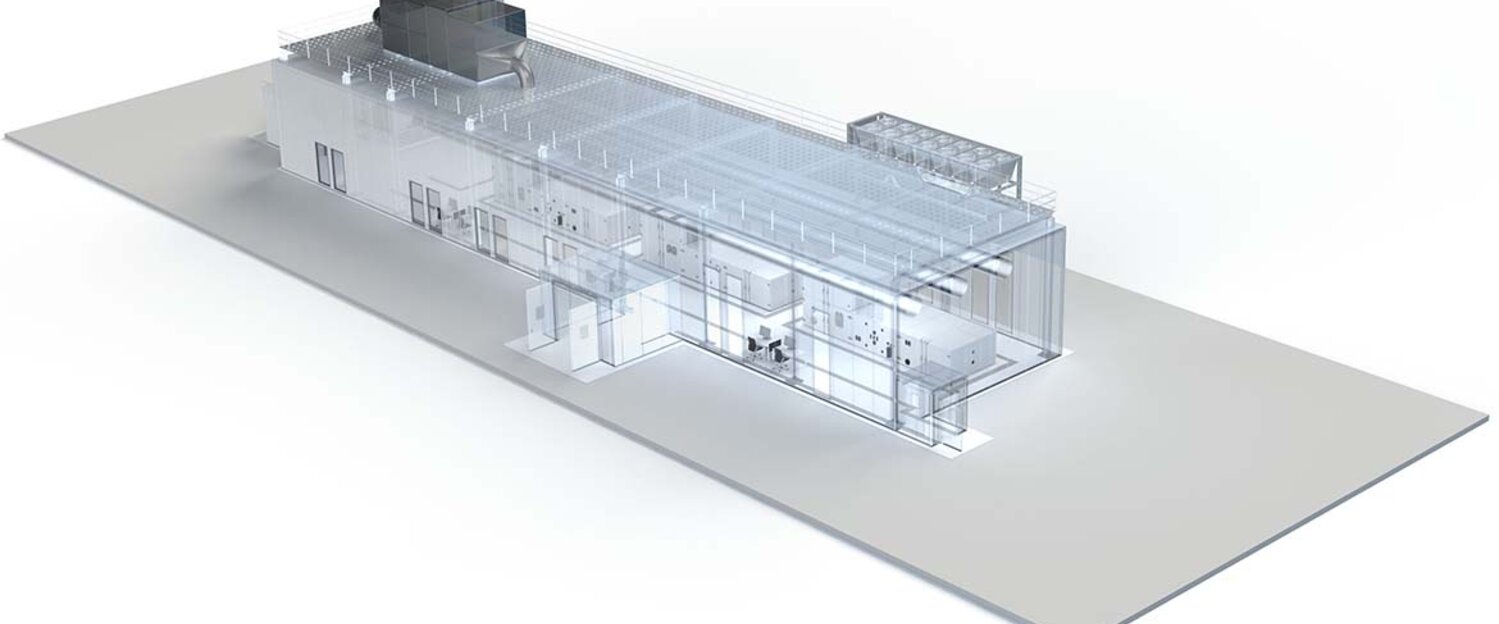

Ten compact dry rooms for battery production

The project includes the construction and air-conditioning of a total of ten individual rooms, some of which have different drying room conditions. These cover a total area of approx. 3000 square meters within the pilot plant. To ensure the highest possible energy efficiency, thereby making production economical, the individual areas are air-conditioned separately or autonomously. The rooms are designed to be as small as possible and as large as necessary in order to optimise the room volumes. By dividing the production into separated rooms, the individual climate conditions and air humidities required for the respective process steps can be precisely regulated at every point. In addition to humidity and air conditioning, air purity also plays an important role in ensuring product quality. For maximum process reliability, the system is planned in such a way as to operate with active leakage minimisation and with the air injected via fine filters.

Particularly efficient overall concept

The dehumidification system used works according to the principle of adsorption dehumidification and is one of the most efficient systems on the market. This is important, because up to 40% of the energy required to manufacture a battery is needed to dry the air. The adsorption dryers with individually dimensioned drying wheels are installed directly above the drying rooms as well as in the technology annexe and reliably ensure the air prepared for the respective process steps with dew points down to -70 °C as required. The air stream to be dried flows through a structure made up of layers of fibre fleece with chemically bonded silica gel and metal silicate and is dehumidified to the required dew point temperatures. In the counterflow, the moisture adsorbed in the silica gel is expelled by means of hot regeneration air. This allows a continuous dehumidification process to be realised.

Room-in-room system kit

In addition to the air-conditioning technology and the adsorption dryers, weisstechnik is also supplying the entire cell and steel construction, including walls and ceilings as well as airlocks, ducts and pipelines. For cell construction, weisstechnik works with a modular kit that has been tried-and-tested in many projects throughout the world and facilitates particularly tight chambers in any size. The ductwork is designed to be particularly low-leakage and to prevent moisture or foreign matter from entering the rooms - another important factor in ensuring process conditions.

Accelerated production by the end of 2022

weisstechnik went straight into detailed planning when the contract was signed. With the help of an optimised assembly process, this will be completed on schedule by the beginning of 2022 so that production, delivery and installation of the plant can begin immediately. The commissioning of the individual rooms will take place successively and should be completed by the end of 2022, but weisstechnik will continue to take care of the systems with regular maintenance and servicing work, including after conclusion of the project. weisstechnik has a unique service network that ensures high plant availability with short travel distances and fast response times.

(4,981 characters with spaces)

Reprint free of charge. Please state Weiss Technik GmbH as a source.