The standard for temperature cycling tests IEC 60068-2-14 has been updated because of improved testing technology. Special focus of the update: the interaction between the test specimen and the test parameters.

With the revision, the standard reflects the current state of environmental simulation technology. The latest empirical values from international laboratory practice have also been incorporated.

The test specimen is at the centre of the modification

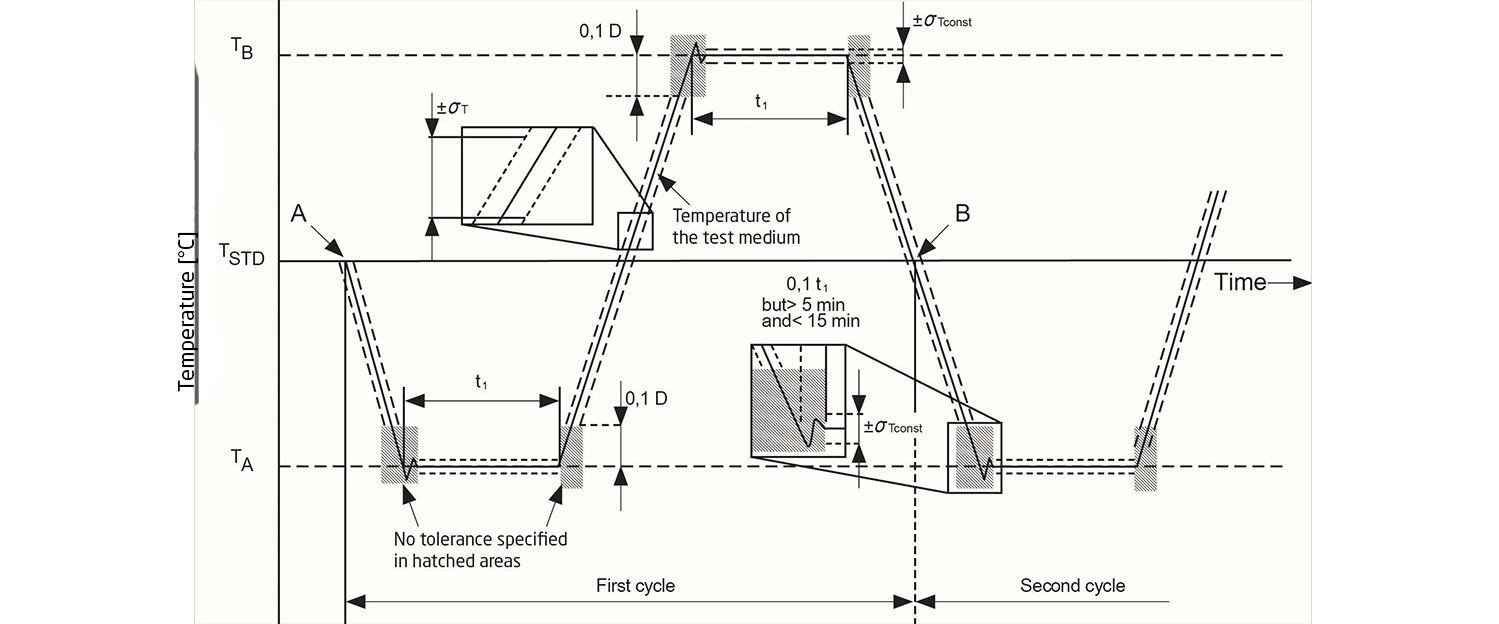

The update of the standard places the test specimen at the centre. This is because every test specimen heats up or cools down differently depending on the material, weight, and processing. Test specimens also react differently to the respective test conditions and show separately occurring wear processes and damage mechanisms. Thanks to the example curves and specified tolerances for the temperature levels, users can analyse the tests according to the new standard even more precisely and compare the results more easily.

For data collection (i.e. for measuring and live logging of the test behaviour), sensors can be attached at many points on the test specimen – supplemented by images from cameras located in the test space of the Weiss Technik devices. The Reiskirchen-based company was also involved in the revision of the guideline and assumed responsibility for the project through Head of Development Christian Haack in his role as Chair of Technical Committee TC 104. According to Hack, he especially “collected user knowledge and practical experience from industry, trade associations, and various international committees in order to incorporate them into the standard”.

Fundamentally consistent test methods

The guideline is primarily designed for the development, validation, and quality assurance of electrotechnical products. It is used to both approve components and detect and trace the causes and mechanisms of damage. Testing is carried out using abrupt temperature jump or shock tests, ramp tests with gradual temperature changes, and tests in which liquid instead of air causes the temperature change.

Because the test methodology was not changed when the standard was updated, laboratories and manufacturers can usually continue to use their existing test facilities depending on the type of test. Weiss Technik devices such as the ShockEvent, TempEvent, ClimeEvent, and LabEvent, some of which can reach temperatures as low as −70°C, are particularly suitable for these tests.

In order to gather further practical knowledge for future updates of the standard, Weiss Technik is asking for input from users. Find the option for submitting assessments and suggestions:

At international level through the International Electrotechnical Commission (IEC)

Reprint free of charge. Please cite Weiss Technik GmbH as the source.