ATEX checklist

Checklist for hazard assessment and categorising testing areas and installation areas into zones.

Download

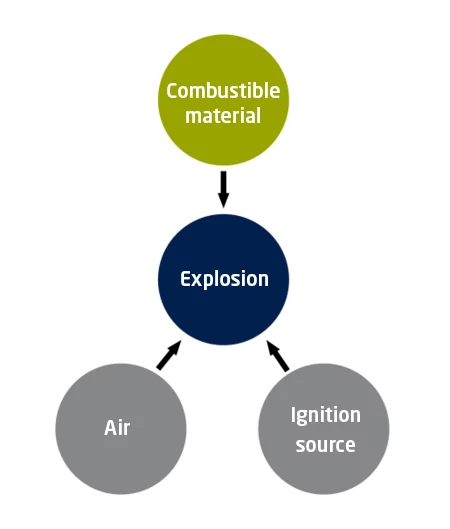

Explosive mixtures can come about intentionally or unintentionally during testing.

Combustible, flammable and explosive substances (e.g. liquid, gas) can be emitted into the chamber from test specimens.

A gas mixture is considered explosive when the gas concentration of the material lies between specific limits.

These limits are known as the lower explosive limit (LEL) and the upper explosive limit (UEL) and are specified in the safety data sheet for the material.

Safety measures are required to compensate for the risk of a fire or explosion.

Our equipment includes vital components which are also potential ignition sources, such as heating units, lighting, etc.

We can modify and add safety features to our equipment to ensure compliance with the ATEX directives.

A variety of information is required for this purpose.

The term ATEX (ATmosphère EXplosible) is used to refer to European Regulations regarding the safe operation of industrial equipment and devices in potentially explosive atmospheres or potentially explosive conditions.

The two relevant directives are Directive 1999/92/EC and 2014/34/EU. Both of these directives are binding, and must be complied with when installing potentially explosive or protected installations.

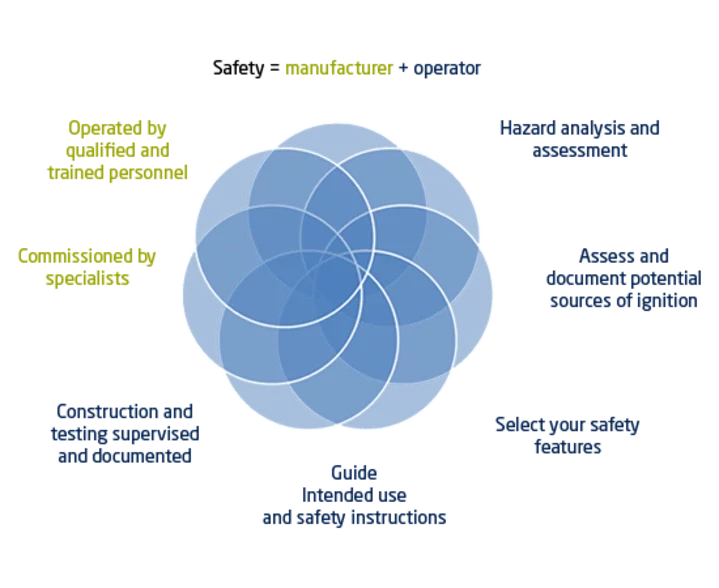

The primary obligation of employers is to assess hazards and classify areas where hazardous explosive atmospheres may occur in zones.

Equipment manufacturers are obliged to label their equipment and assign them to so-called “equipment categories” based on the risk of them igniting explosive mixtures. This obligation also represents the link between plant operators and equipment manufacturers.

1. Perform a hazard assessment

Plant operators are obliged to assess the hazards posed by both work equipment and facilities which require supervision.

2. Prepare an explosion protection document

Operators and/or equipment manufacturers must implement explosion protection measures which are appropriate for each hazard.

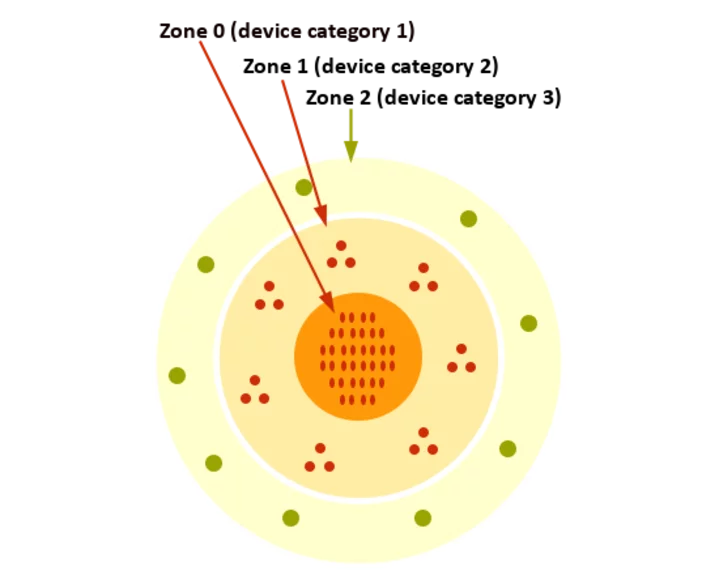

Zone 0:

A place in which an explosive atmosphere is present continuously or for long periods or frequently.

Zone 1:

A place in which an explosive atmosphere is likely to occur in normal operation occasionally.

Zone 2:

A place in which an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Our temperature and climate chambers are assigned to equipment group II in accordance with Directive 2014/34/EU. This equipment group is divided into 3 categories.

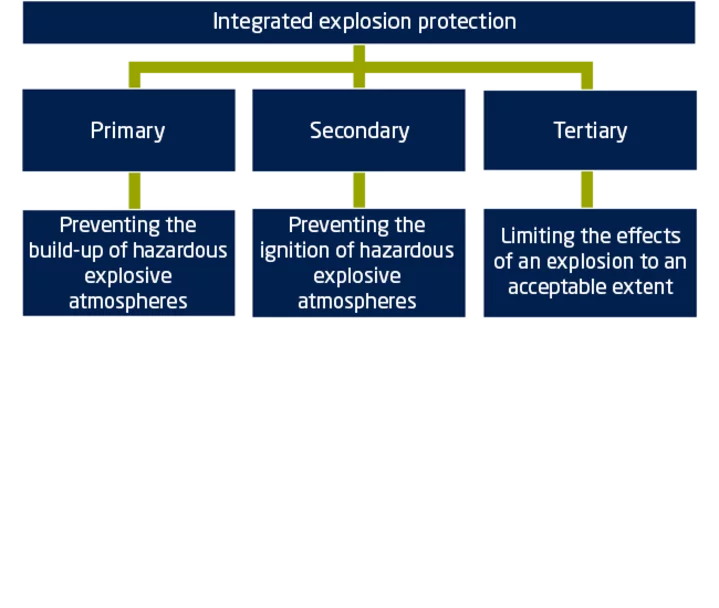

Explosion protection begins with primary explosion protection measures. Secondary explosion protection measures are used if the primary measures cannot ensure an adequate level of safety or if the primary measures cannot be used. Tertiary explosion protection measures are only considered if it is clear that neither primary nor secondary explosion protection measures can be implemented.

Checklist for hazard assessment and categorising testing areas and installation areas into zones.

Download