Lunchtime: the sun is shining and the table is set. Martha Willmot arrives in a smart casual outfit with an iPad under her arm. The mechanical engineering graduate quickly chooses Pane Rustico. Between food and coffee, she talks about a highly exciting development project for the production of lithium-ion batteries.

Ms Willmot, you are currently managing a development project. What is it all about?

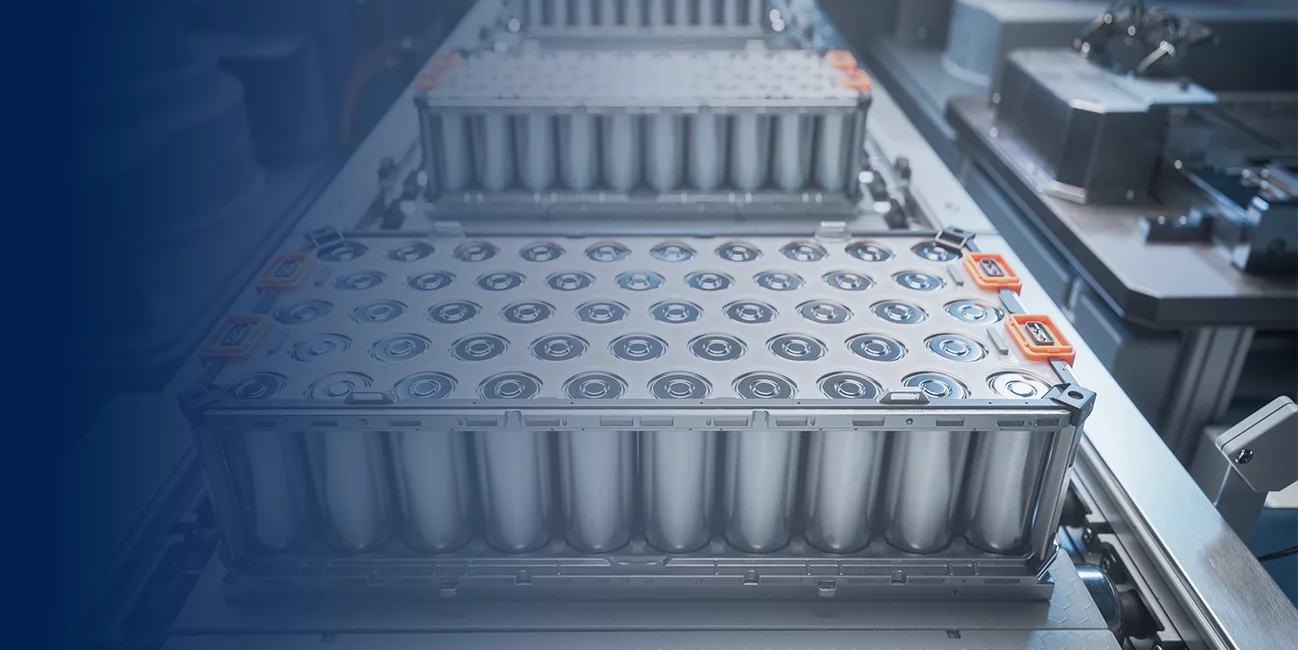

In short, mini-environments for the production of lithium-ion batteries for electric cars and other applications. The QueEn project, funded by the German Federal Ministry of Education and Research, aims to develop new ways of producing high-quality, energy-optimised high-performance batteries in Germany and Europe.

Are you carrying out the project alone?

No, the development team at Weiss Klimatechnik is working as part of a consortium. This includes the Fraunhofer Research Institution for Battery Cell Production FFB, the Fraunhofer Institute for Manufacturing Engineering and Automation IPA, the equipment manufacturer FFT Produktionssysteme, and the company Varta, which brings its battery expertise to the table.

What is your role in the project?

Dry, temperature-controlled and low-particle air is the key factor in battery production and in the project. At Weiss Klimatechnik we are developing the turnkey centrepiece of the system. As a project manager, I make sure that we create the special climatic conditions in the air needed to produce lithium-ion batteries in an energy-efficient and safe way.

Why is the development of new solutions for dry air so important?

Because the materials required for Li-ion batteries are extremely sensitive to moisture. If they come into contact with water, highly toxic hydrofluoric acid and undesirable oxidation products are formed. On top of this, the new materials that make it possible to achieve higher energy densities are even more sensitive to moisture. Although dehumidification solutions already exist, they require a lot of energy. This means that production at German and European energy prices is not marketable compared to many Asian locations. The energy-intensive dehumidification process also has a negative environmental impact.

How is battery production currently being handled?

At the moment, production takes place in large clean and dry rooms, which require a significant amount of dry air. Employees wear cleanroom or protective clothing and can only stay in the room for a limited time. They release around 110 to 120 grams of moisture per hour, which requires a lot of energy to remove. In this project, we use mini-environments that we arrange with the consortium in a fully interlinked process with clustered process steps and airlocks. These mini-environments are located in a room with lower climatic requirements and are specifically designed to create the necessary conditions at the point of use, where battery production actually takes place. This approach saves a lot of energy and is much more cost-effective.

What kind of savings potential are we talking about?

Depending on the application, between 26% and 43% of the energy used in battery production is consumed just to create the necessary production conditions, according to studies by the Fraunhofer Institute, among others. The dry rooms currently in use need to be supplied with up to 16,000 m³/h of dry air an hour for each person working in the room, all at extremely low dew points. This gives you an idea of the scale we're dealing with here.

Can you elaborate on that?

Yes. At present, production requires a dew point of -40°C. In the future, it will need to be as low as -60°C. Lowering the dew point from -40°C to -60°C means that the amount of air required increases by about a factor of 12, which significantly increases energy consumption and makes production less cost-effective. The Fraunhofer Institute (FFB) has shown that mini-environments offer a huge savings potential of around 77% over ten years.

What conditions are required for the manufacturing of lithium-ion batteries?

The most important factor in a safe manufacturing process is dryness. It ensures quality and prevents accidents. Air purity also plays a crucial role in preventing particles from contaminating materials. However, in terms of air management, this is the lesser challenge - one that we are very familiar with and have mastered through numerous cleanroom projects.

How are you approaching the project from a technical standpoint?

At Weiss Klimatechnik, we have extensive experience with dry air and battery manufacturing. We are also well-versed in air management and pressure control in smaller environments, such as isolators. Building on this expertise, we are now developing a new solution that meets the high demands for process climate control.

What technology are you using for this?

In terms of drying principles, there is no alternative to adsorption drying. That is why we have analysed the process in detail and identified important areas where we can make adjustments. Without going into too much detail, I can say that we have found some great new approaches to materials, pressureand controls.

What changes have you made to the control system?

Our mini-environments are very compact. This provides new opportunities for optimisation compared to a large room. We can accurately measure and condition the air and humidity to create the exact conditions required at the point of use. If necessary, we - or the customer - can make adjustments much more quickly and effectively. Thanks to our extensive portfolio, we can supply cleanroom and drying technology, including air dehumidification, that is perfectly matched and integrated into the mini-environments.

How far along are you with your part of the project?

We currently have a working prototype in a mini-lab measuring just under 30 m². The proof of concept is underway and the initial tests are looking promising. The project plan is to deliver two prototypes to the Fraunhofer Institute at the end of the year, where they will be integrated into the overall demonstrator. We will then look at the results and make further improvements. There is still a lot to do before the end of the project in June 2026.

Can you share something about the revisions to the control system and software?

Just this: We see great potential in our concept, which we will be patenting. Everyone can look forward to seeing how it will be implemented.

Thank you very much, Martha Willmot, for the interview.

Information snippets M. Sc. Martha Willmot

Martha Willmot studied mechanical engineering, specialising in energy systems and materials science. After four years developing new appliances at Weiss Klimatechnik, she now works in product management and is project manager for the strategically important QueEn project. After work, she enjoys trying out new things, including cooking, when she prepares recipes from all over the world.