Quick and easy to test in compliance with standards

The mobile Plug&Test Lab

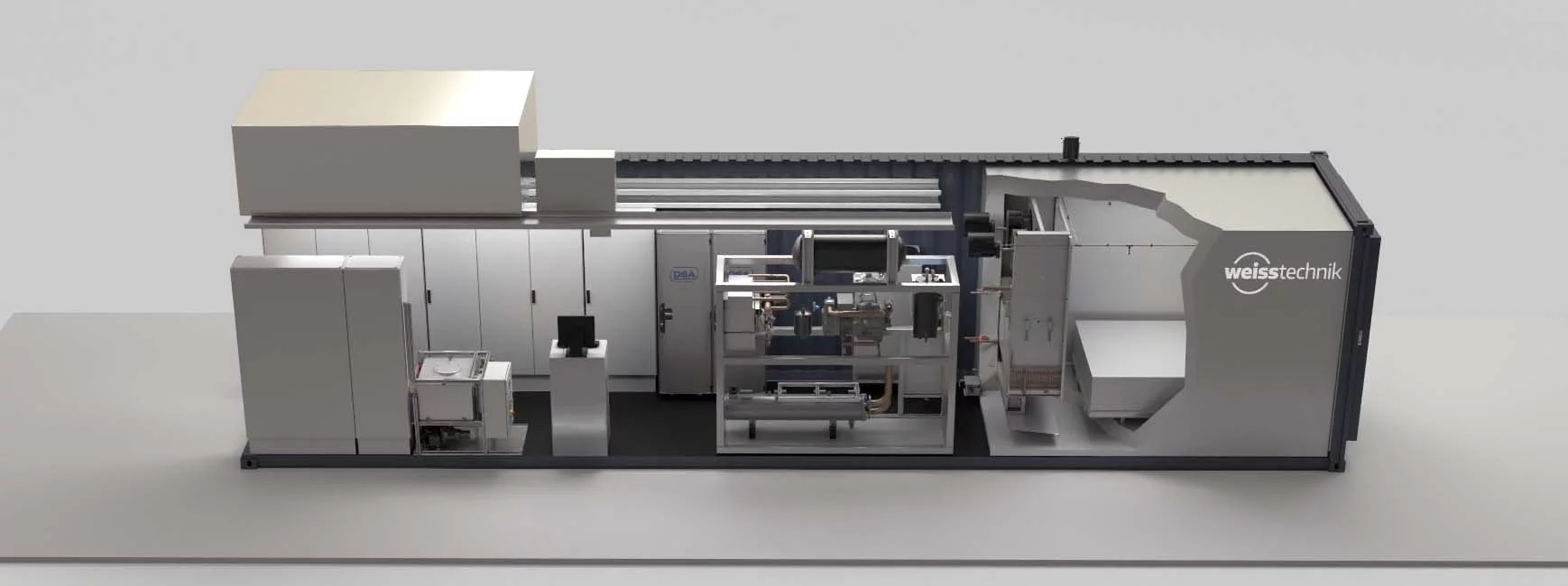

The market for electric vehicles is on the move, and the pressure to innovate in the e-mobility sector is increasing rapidly. As a result, the demand for quickly available test solutions for standard temperature and climate tests of lithium-ion batteries for vehicles is correspondingly high. With the Plug&Test Lab, Weiss Technik and DSA have developed a mobile solution for standard-compliant testing that meets all the necessary safety requirements.

Video

Plug&TestLab.mp4

Developed with the know-how of two highly specialised companies

Weiss Technik as a long-time experienced and worldwide leading specialist for environmental simulation and DSA as a leading expert for innovative customised diagnostic solutions for vehicle electronics have combined their competences. The result of this perfect combination is the Plug&Test Lab, the mobile solution for all standard-compliant testing of electrical energy storage systems. Weiss Technik was responsible for the container construction, air-conditioning technology and project coordination, while DSA contributed the hardware and software for the container automation, measurement technology, DUT contacting and the higher-level safety PLC.

Mobile, efficient and multifunctional:

The mobile test container, designed as a Plug&Test system, is suitable for expanding existing test capacities, as a replacement for test systems that have failed at short notice or as a cost-effective set-up for new test locations such as start-up companies. It offers the highest level of testing comfort and safety equipment in accordance with Hazard Level 6. Thus, it not only covers a wide range of tests for high-voltage batteries, but also relieves your own personnel.

Large test spectrum on a small footprint

Fully equipped with climate control technology, the Plug&Test Lab can handle temperatures from -40 to +80 °C with a temperature change rate of 3 K/min. and humidity levels from 10 to 95%. Thus, the container masters short end-of-line tests and prototype tests as well as long-term tests. Even own test scenarios can be programmed after a short introduction. At the same time, the test editor and test tools enable a wide variety of electrical and physical tests of the battery management system and individual components. All services take place within the compact 40-series container, which nevertheless offers enough space inside for a complete test laboratory including a test chamber, a battery charging/discharging unit, for measurement technology as well as test stand automation and cooling water coordination.

Equipment

- Test chamber

- Test item (battery pack)

- Air treatment unit

- Refrigerating machines

- Operating station

- Extinguishing system

- Refrigeration control cabinet

- External condenser

- Charging/discharging station

- Air-conditioning splitter

- Central automation system

- Media conditioning system

- Decentralised automation system

Your advantages:

- Mobile stand-alone test laboratory, ready for use in the shortest possible time

- Compact solution for end-of-line, prototype and long-term tests

- Climatic test chamber with safety equipment according to. Hazard level 6

- Cost-effective set-up of new test locations

- Simple expansion of existing test capacities