Hospital

Clean air systems for operating theatres

How an optimal hygiene climate can protect patients & operating theatre staff from dangerous germs.

Even if hygiene standards in operating theatres are very good, inadequate air hygiene can lead to considerable risks. Patients fear infection with multi-resistant germs, which are an increasing problem, especially in hospital environments. And doctors and operating theatre staff are also at risk from so-called surgical smoke, which can cause permanent damage to their health. But with the right clean air systems, doctors and patients can be effectively protected.

Specific requirements

The clean air quality in operating rooms is an important factor for the success of a surgical procedure. Hygienic safety depends to a large extent on airborne germs. Their importance can be easily illustrated: The fewer particles in the air, the fewer germs can settle on it and the fewer infections they can cause. Furthermore, it is elementary to protect patients and operating theatre staff from surgical smoke. Our clean air systems are suitable for a wide variety of structural conditions, hygienic requirements and surgical areas of application - so that infection prevention and workplace safety are always guaranteed.

Standards & guidelines

In principle, strict regulations apply to operating theatres:

- Microbial air purity of the supply air: guideline value 4 CFU/m3, limit value 10 CFU/m3,

- Particle load of the supply air (particle diameter > 0.5 µm): guideline value 4000/m3, limit value 10000/m3 [15],

- Temperature range: 22 to 26 °C (exceptions in neonatology/paediatrics or in special situations),

- Relative humidity 35 to 65 %,

- Air velocity maximum 0.2 m/s,

- CO2 content < 0.1 vol.%.

Reliable systems also meet national and international norms and standards:

- DIN 1946 T4

- HTM 03-01

- SNI

Solutions

Operating theatre clean air ceilings must meet the highest requirements in order to provide ideal protection for patients and staff. That's why we offer customised clean air systems with low-turbulence displacement flow (TAV) from a single source. Our approach is obvious: we want to monitor the particle load in the air during operations and adjust the air supplied via the operating theatre ceiling as required. This means: few particles: low airflow, more particles: stronger airflow. This is not only good for the patients, but also better protects the operating theatre staff from the dangers of surgical smoke. In addition, demand-responsive airflow reduces noise pollution and lowers energy costs.

Our clean air solutions adapt to your structural requirements:

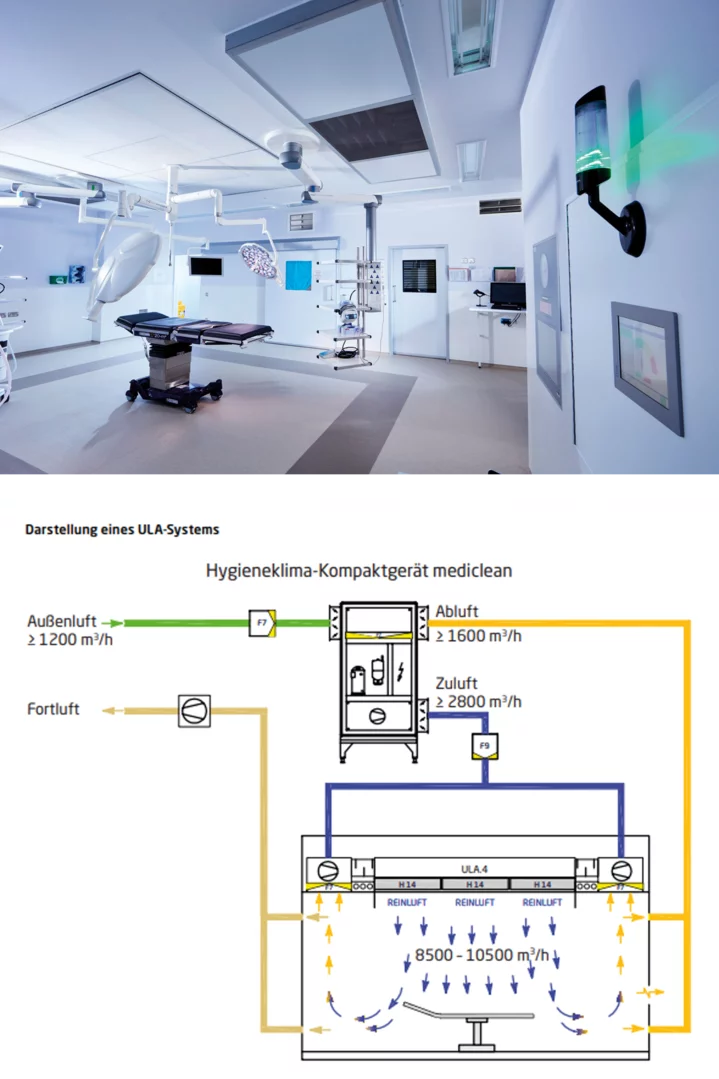

Recirculating air ceilings (ULA) are fully integrated into the false ceiling and are also suitable for the renovation of existing facilities.

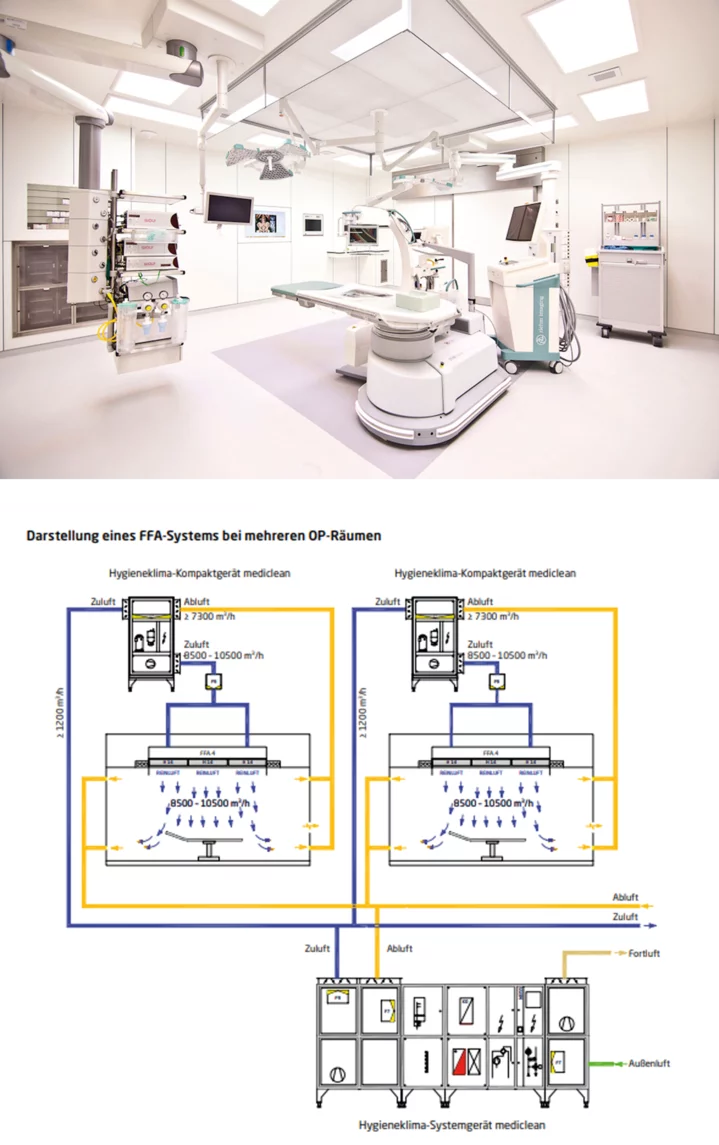

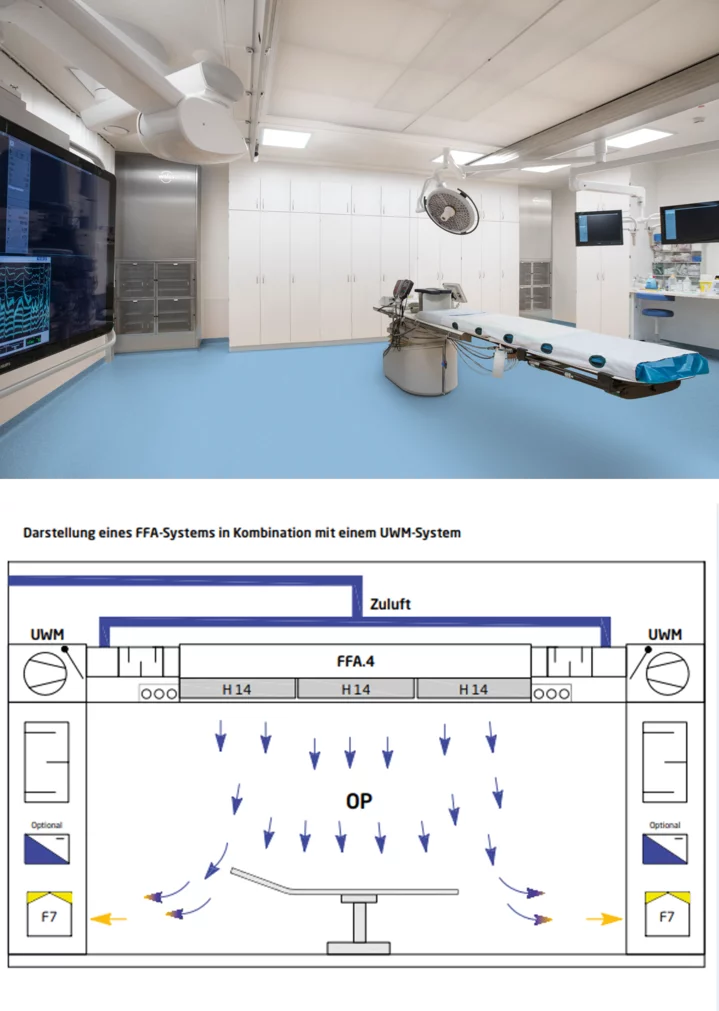

Filter area ceilings (FFA) are often the best solution when the air handling units are located in an adjacent room.

Wall-mounted recirculation modules (UWM) are especially suitable for use in operating theatres with insufficient space for ceiling-mounted recirculation modules.

Recirculating air ceilings

Functionality

The optimised, low-turbulence recirculation ceiling consists of an air outlet element, terminal HEPA filters, a pressure body with silencers and recirculation modules. To ensure maximum safety with optimum efficiency, the ULA mixes room and supply air in the recirculation module. For this purpose, the room air is drawn in via the recirculation module and mixed with the supply air coming from the air handling unit. The mixed air is conveyed into the pressurised body located above the filters. From there, it is fed particle-filtered as clean air into the operating room and the set-up room, where it creates a protected area.

Protected area

The protected area is created by a low-turbulence displacement flow (TAV). It encompasses the entire aseptic environment of the surgical procedure. This also includes material and instrument tables as well as sterilely dressed persons. Thus, patient, surgical team, material and instruments are optimally protected against particles and airborne germs. The size of the protected area is marked on the floor.

Advantages:

- Optimum energy consumption

- Reduction of duct cross-sections coming from the A/C unit

- Air volume adjustment possible independently of the air handling unit and duct system

- Mixing of room and supply air in the recirculation module, i.e. outside the ceiling corpus, and thus no temperature differences

- For refurbishment of existing systems

Operating theatre filter surface cover

How it works

The OR filter surface ceiling is supplied 100% with air from the air handling unit. This air is conveyed via the duct system into the pressurised body located above the filters. From there, it is fed particle-filtered as clean air into the operating room and the set-up room, where it creates a protected area.

Protected area

The protected area is created by a low-turbulence displacement flow. It encompasses the entire aseptic environment of the surgical procedure. This also includes material and instrument tables as well as sterilely dressed persons. The patient, surgical team, material and instruments are thus optimally protected from airborne particles and germs. The size of the protected area is marked on the floor.

Your advantages:

- Mixing of supply and circulating air directly in the air-conditioning unit

- Measuring connection for feeding and measuring the test aerosol easily accessible

- Suitable for low false ceiling heights

Recirculation wall module

Function

The recirculation wall module can be installed either in front of the wall, as an integral part of a lightweight wall or in an adjacent room. The recirculated air is drawn in from the operating room directly at the recirculation wall module via lint separators, filtered, guided through silencers and optionally cooled. Subsequently, the recirculated air is conveyed by the fan with the supply air coming from the air handling unit into the pressurised body of the filter surface ceiling located above the filters.

Your advantages:

- Reduced sound pressure level when installed in the adjacent room

- Service and maintenance work can be carried out from outside the operating theatre

- Lint separator easily accessible and designed for mechanical cleaning

- Optional use of a dry cooler

Video

With our new contact filter, you can find the right contact person for your request in no time—quickly, specifically, and personally.

Simply filter, select a contact, and get started right away!

Hygienic Climate

Service

There are no contacts available. Please make a selection.