Heuchelheim, April 2, 2024: Visit Schunk at Achema 2024, the leading international trade fair for the process industry. In Hall 8, the materials specialist will be presenting high-performance carbon and ceramic materials for reliable system operation in the pump, compressor and sealing industry.

Avoid leakages with blister-resistant mechanical seals

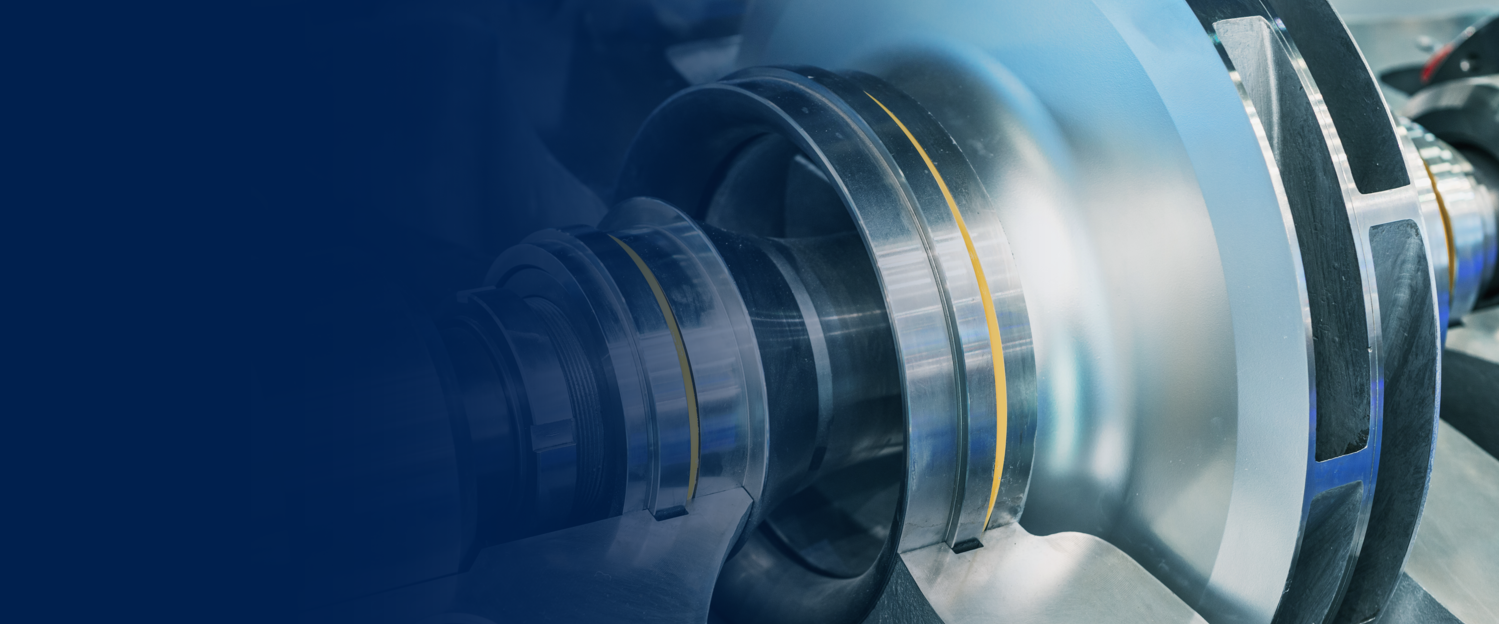

One of the highlights at the Schunk booth G93 is PrimeCarb®. The material pairing for mechanical seals was specially developed to prevent blistering. This problem mainly occurs when highly viscous oils have to be sealed at low temperatures. Blisters on mechanical seals in dynamic seals can lead to leakage and are often the cause of failures in industrial pumps and compressors.

Mechanical seals made from PrimeCarb®, on the other hand, are extremely durable and can withstand even the demands of highly critical applications. The blister-resistant Schunk solution therefore stands for high operational reliability, a long seal service life and lower life cycle costs. In addition, PrimeCarb® is the more cost-effective alternative to silicon carbide ceramics in hard/soft pairings.

Save time and money with split seal rings with emergency running properties

More safety and lower costs are also offered by seal rings made of the Schunk material CarSIK-CT. Their design enables plant operators to split the seal ring without losing the sealing effect and to replace it if necessary without having to completely remove the shaft.

Another advantage of CarSIK-CT: The material combination of silicon carbide and graphite provides additional lubrication and therefore ensures reliable running even if the seal rings are insufficiently lubricated. In contrast to graphite-free solutions, customers benefit from the reliable performance of their systems for a certain period of time in the event of irregularities, even in pump operation with very small quantities of medium.

Schunk at the Achema 2024

June 10 - 14, 2024

Frankfurt on the Main

Hall 8

Booth G93